Extraction facilities use various methods, each with unique processes and building requirements. An extraction facility must meet applicable building code guidelines, equipment requirements, and safety regulations in order to gain approval to operate. Denial of an application for an extraction facility can typically be appealed through a hearing within a certain period of time.

While certainly not exhaustive, here are some general guidelines that can be applied to most jurisdictions. Following these guidelines will not ensure regulatory compliance but are a good starting point for obtaining approval.

Building Code Guidelines

- Electrical components shall be ground-fault protected and explosion-proof where necessary

- Fire-rated walls, doors, and sprinkler systems for extraction areas

- Hazardous exhaust system for flammable vapors; equipment must be approved for heating flammable liquids

- Explosion-proof ventilation and purge system

- Emergency ventilation systems with backup power

- Gas detection monitoring system and alarm

Related:

6 Commonly Overlooked NFPA Regulations for Marijuana Extractors

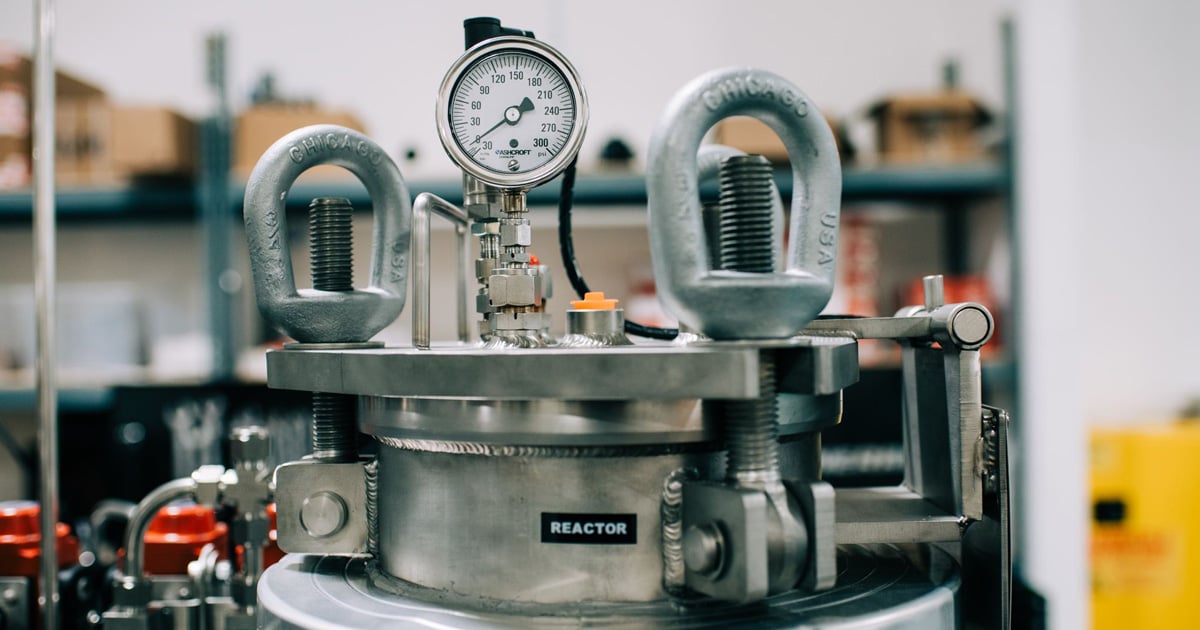

Extraction Equipment

Extraction equipment and post-processing equipment used for purification and winterization that use hazardous materials are required to be listed with quantities and storage method in the approval process.

- Only closed-loop equipment can be used

- Open blast extraction is prohibited

- Because there is no listing available for compressed-gas extraction systems using hazardous materials, equipment must undergo a thorough engineering inspection by a professional mechanical engineer

- Any modification or relocation of equipment voids the approval

- Refrigerators used to store or process flammable liquids shall be rated to store flammable liquids

- Vacuum ovens must be rated to process volatile gases if volatile gases are used

Safety Regulations

ASME B31.3

For process pipe fabrication, the American Society of Mechanical Engineers' (ASME) B31.3 code provides specifications for the pressure design requirements of high-pressure pipes. The code ensures that the construction can withstand the desired extraction process.

Consider B31.3 for material selection, thermal expansion, and support design. Common considerations for pipe fabrication include:

- Corrosion resistance to determine pipe wall thickness and material for pipe, gaskets, and valves

- Hydrostatic test limits for minimum test pressure specifications for varying design pressures and temperatures

ASME BPVC Sect. VIII, Div. 1

Use the ASME Sec VIII, Div. 1 code to calculate the thickness measurement for pressure vessels that operate at pressures exceeding 15 psi (either internal or external).

This section also addresses connections and bends in pipes and welded branch reinforcement with specifications for temperature, materials, and pressures.

Extraction facility requirements vary by municipality, but staying on top of the latest building code guidelines and fire code regulations will keep manufacturers compliant and ready to continue their operations. Adhering to building code guidelines can keep extractors safe and ready for any type of emergency.