Cannabis degradation is the natural process of decay of the cannabis plant. Immediately after the buds are harvested, the quality of the flower begins to change. Cannabinoids like THC convert to THC analogs (CBN), losing out on its original potency. However, this natural process is becoming an increasingly popular option in the removal of THC in hemp products.

Here, we discuss the organic conversion process that occurs in the plant, how it affects customers and cannabis companies, and how both can improve freshness by limiting exposure to light, air, humidity, and heat.

What Is THC Degradation?

Delta-9 tetrahydrocannabinol (THC) degradation occurs naturally with age and exposure to heat, light, air, and humidity. For consumers, cannabis flower in improper or long-term storage can experience a gradual change in quality. As a result, improperly stored buds can feel and look dry and slightly duller in color.

After harvest, cannabis buds usually undergo a drying and curing process to remove excess moisture and bring out the strain’s natural flavors and aromas. A flower’s chemical profile changes on a scientific level, reducing the THC potency.

THC degradation is a natural process that occurs even in the most optimal storage environment. Like any perishable product, cannabis flower has a limited shelf life. According to some research, cannabis loses about 16 percent THC after one year, 26 percent after two years, 34 percent after three years, and 41 percent after four years.

What Is CBN?

As cannabis ages, its terpenes evaporate, and THC converts into another cannabinoid. The organic process produces cannabinol (CBN), a minor compound known for its sleep-inducing effects. That is why users may notice an increased couch lock effect after smoking aged buds. Instead of feeling the euphoric high of THC, they may feel a sedating effect.

How Do You Know If THC Content Decreased?

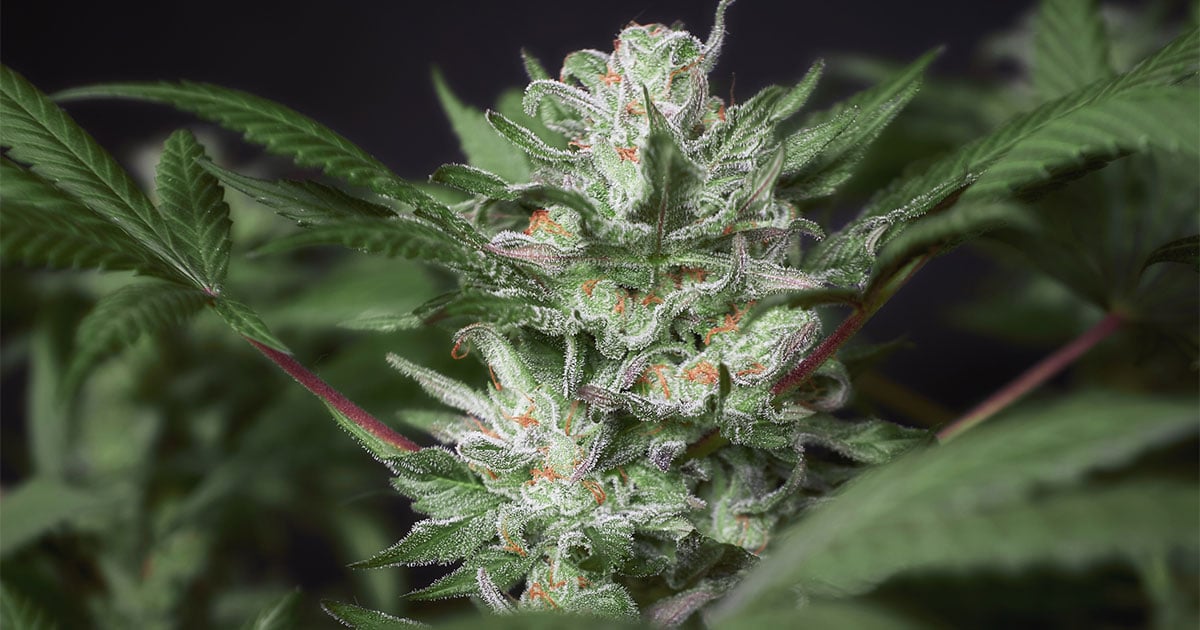

Cannabis degradation is visible to the naked eye. Cannabis buds have resinous trichomes glands, the source of the cannabinoids, terpenes, and other compounds in the cannabis plant. Trichomes develop during the plant’s flowering stage, begin as a clear gland, turn milky white, and finally turn an amber color.

Generally, growers harvest the cannabis plant when about half of its trichomes have turned amber, indicating peak terpene and THC content. As it undergoes a drying and curing process and gets stored at a dispensary and at home, the trichomes continue their degradation process. The darker the trichomes get, the more THC degradation has occurred.

Cannabis degradation can be slowed down with the appropriate storage methods. Controlling the following environmental factors can reduce the speed of degradation: air, humidity, temperature, and light.

Temperature

Hot and cold temperatures both affect THC degradation. Cannabis buds should be stored in an airtight container in a space that does not go above 70º F. High temperatures can increase the risk of bacteria and mold growth in the crevices of the buds.

Cannabis terpenes, in particular, are vulnerable to heat. Compared to cannabinoids like THC and CBD, monoterpenes evaporate at a low temperature. As a result, heat exposure can degrade terpenes and reduce the buds’ aroma and flavor.

Long-term exposure to high temperatures can decarboxylate cannabinoids and accelerate the degradation process. On a molecular level, the acidic THCA compound loses a carboxyl ring during this process, converting it to the delta-9 tetrahydrocannabinol (THC) compound. Flash forward through the degradation process, and the THC eventually converts to CBN.

The relative humidity levels can rise when exposed to extended cold temperatures, such as when stored in a refrigerator or freezer. When humidity increases, the moisture can accumulate on the buds’ bracts and their trichomes, breaking the trichomes down in the process.

Humidity

High relative humidity levels can speed up THC degradation by adding more moisture to the buds. Drying and curing cannabis at optimal humidity levels ensures the THC is not destroyed. Industry experts recommend storing cannabis in spaces with a relative humidity between 59% and 63%. Anything higher or lower can significantly affect the quality of your buds.

When high humidity levels are introduced into your flowers, the risk of mold formation increases. On the other hand, cannabis flower should not be excessively dry either. Removing too much moisture from the environment and the buds can make them brittle and harsh to smoke, vape, or dab.

Light

Light, whether it be artificial or natural UV light, speeds up the THC degradation process. Prolonged exposure to UV rays can destroy the stored plant material. For this reason, we recommend keeping your cannabis flower stored in a dark place with limited or no exposure to light.

Air

High concentrations of oxygen can negatively affect the quality of cannabis flower. When exposed to oxygen, cannabis can degrade more rapidly than in a contained environment with limited oxygen. Therefore, high exposure to oxygen can speed up the conversion of THC to CBN.

How THC Degradation Can Hurt Cannabis Companies

Cannabis storage, through every step of the supply chain, extends its shelf-life and increases its value, while limiting the decrease of THC. Cannabis cultivators, retailers, processors, and distributors must pay close attention to terpene and cannabinoid degradation to ensure they protect their bottom line and reputation.

Here are just a few reasons why the degradation of THC is so crucial to cannabis companies:

- Storage time - Cannabis requires proper storage throughout its journey from a cultivator to a processor or a retailer. While it sits in the back room or on a dispensary shelf, THC begins to degrade to CBN. A quick turnover of products is essential for brands to deliver quality flower.

- Brand prestige - Excessively degraded cannabis products sold to customers can create a negative reputation. While some factors that worsen degradation are out of a brand’s control, there are many strategies to maintain cannabis flower freshness to keep customers happy.

- Cannabis extraction - Cannabis processors create infused products that require the most THC possible to produce a high yield. Dried plant material that has suffered from extreme temperature, humidity, air, or light exposure reduces the concentration of THC and increases CBN levels, producing a smaller yield of THC.

How Can THC Degradation Benefit Extraction Companies

Among cannabis extractors, THC degradation is quickly becoming an asset instead of a liability. Generally, processors want to maintain high levels of THC in their raw cannabis to meet the high demand for THC-rich products across all markets. However, some markets may require THC-free products to remain federally compliant.

For cannabis extractors who need to perform THC remediation, chromatography has helped filter out THC in a quick manner, although it requires higher expenses for equipment and filter media. In an effort to lower their expenses while removing THC, many extractors have turned to the natural degradation process.

However, the natural process can take significantly longer than traditional chromatography methods. Some extractors are experimenting with ways to speed up the months or years-long process to just a matter of days.

In place of a cost-effective way to naturally degrade THC, processors must use high amounts of chemical solvents to remove THC that is then disposed of. Natural degradation allows them to preserve more of the CBD and terpenes and convert the unwanted THC into a therapeutic and non-intoxicating CBN.

With chromatography, processors risk losing yield and raising their operating costs. If done correctly, processors can run biomass through the heat in a slight vacuum to convert the THC to CBN, all without the need for solvent and purging.

Currently, chromatography is the best way to meet the large-scale demand for CBD products in the U.S. and abroad. In addition, CBN is prohibited in some countries like the United Kingdom. In the U.S., CBN may be considered an illegal analog of THC, putting it in a legal gray area for processors. For international markets, chromatography may be the best THC remediation option.

Luna Technologies: A Full-Spectrum Solution for BHO Extractors

Luna Technologies’ IO Extractor provides BHO operators with the capability to create a wide range of cannabinoid products, ranging from distillate and isolates to high-terpene full-spectrum products like terp sauce. No matter what your customers are seeking, Luna’s cutting-edge, automated technology harnesses the power of light hydrocarbons to preserve the plant’s cannabinoid profile in the final product.